DeltaHawk Engines, builders of a revolutionary FAA-certified jet-fueled piston engine for general aviation aircraft, has recently completed advanced simulation analysis of a new, hydrogen-fueled variant of its engine family for multiple markets.

These tests have demonstrated DeltaHawk’s highly adaptable engine architecture is suitable for hydrogen fuel, and that the company’s patented engine design has applications in a variety of markets in addition to aviation – including zero emission vehicles (ZEV), other commercial power applications and multiple defense platforms.

The use of proven internal combustion engine (ICE) technology with hydrogen fuel replaces more expensive, highly infrastructure-reliant, fuel cell systems. A hydrogen-fueled internal combustion engine also has higher tolerance for hydrogen impurities compared to fuel cells and, importantly, allows leveraging of the existing depth of ICE manufacturing knowledge and extensive service networks.

The DeltaHawk engine design itself has numerous other advantages, such as reduced development costs and time to market, as well as higher durability and cost effectiveness due to its more mature technology. In addition, DeltaHawk’s engine design has a significantly reduced power degradation curve over time compared to current fuel cell technology, allowing for better fuel economy than fuel cells after the initial period. Combined, these attributes will enable a more rapid adoption of hydrogen power worldwide – especially with recent global government incentives for hydrogen in commercial trucking and delivery vehicle infrastructure and in military mobility applications.

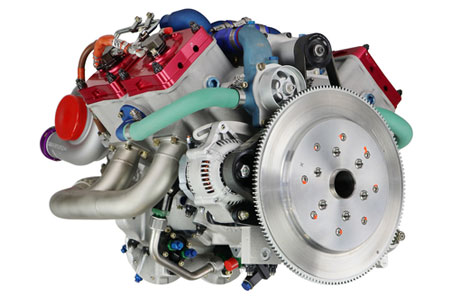

As a result, DeltaHawk is now leveraging its aviation engine architecture to create new variants of its engine family that will use hydrogen fuel in additional applications. The compact, lightweight, and durable DeltaHawk design, based on patented two-stroke technology, makes this new engine family an ideal solution for hydrogen fuel. Though other commercial vehicle engine manufacturers have explored conversion of their ICE powerplants to hydrogen power, DeltaHawk’s testing in computer simulations is proving superior to legacy four-stroke engine architectures.

“Environmental responsibility is a foundational pillar of our company,” said Christopher Ruud, Chief Executive Officer of DeltaHawk. “In the general aviation industry, our family of engines are creating a highly reduced net carbon footprint coupled with airborne lead removal, thanks in large part to their fuel efficiency and capability to burn next generation sustainable aviation fuels (SAF). Now, with our planned ability to expand our engine family to include variants that will utilize hydrogen fuel in aviation, commercial and military applications, we’ve taken another major step toward environmental sustainability, climate neutrality and a zero emissions future.”

About DeltaHawk:

Based in Racine, Wisconsin, DeltaHawk is a privately held manufacturer of advanced-design FAA- certified piston engines for general aviation aircraft and hybrid power systems. DeltaHawk holds numerous patents for its clean-sheet engine designs, and its team of engineers, designers, manufacturing specialists, and certification experts is building an entirely new generation of revolutionary piston engines. In addition, the company recently launched a new program to develop variants of its engine family that will utilize hydrogen fuel in a wide variety of applications including – aviation, commercial road vehicle and military mobility.

For more information, please visit www.deltahawk.com.