As customer demand and regional legislation regarding powertrain choices continues to evolve, Amsted Automotive is ideally equipped to provide efficient torque-transfer solutions. Amsted will display a cache of multi-functional clutch technologies with benefits in ICE, EV and HEV platforms at the 24th annual VDI Dritev Congress.

VDI Dritev focuses on automotive powertrain topics and innovation. This year's event takes place June 12-14, 2024 in Baden-Baden, Germany, bringing together more than 600 experts in the automotive industry. The Amsted display will be in booth #58.

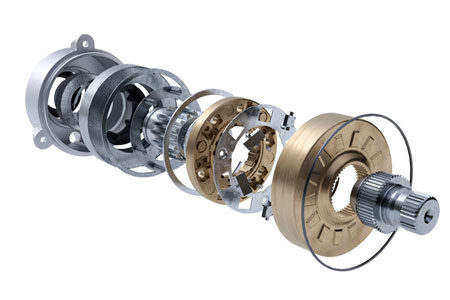

John Jennings, Amsted Director of Innovation and eMobility, will present the latest Amsted multi-functional clutch system, enabling next-generation multi-speed EV powertrains. These systems use Amsted Dynamic Controllable Clutch (DCC) technology One-Way-Clutch (OWC) already used in a production EV all-wheel-drive vehicle since 2021. The technology can be used in both parallel-axis and co-axial powertrain systems. One variation eliminates friction clutches for reduced drag, improved efficiency and improved sustainability metrics.

The company will also display its eAxle disconnect system. This technology enables seamless and quick engagement and disengagement of a drive axle in all-wheel-drive and four-wheel-drive EVs. It also features a Bi-stable magnetic latch, eliminating power consumption while in state. Overall, the improved efficiencies with the Amsted eAxle disconnect system provide for up to 10-percent extended driving range.

Both the of these systems have advantages over dog-clutch style systems:

No blocked or interrupted shifts

No ratcheting during shifts

Simplified system controls

Additional functionality such as park-lock

Easier calibration, reducing engineering loads

Additional Amsted technologies on display include an innovative wheel-end disconnect system designed for commercial vehicle applications and torque management systems using unique Amsted Controllable Mechanical Diodes (CMD) and Mechanical Diodes (MD) in production automatic transmissions. The use of Amsted CMD and MD technologies in these transmissions reduces drag and friction, and the system also minimizes packaging space and mass.